Services

Jaco Machine’s Services

Jaco Machine provides the highest quality CNC milling, CNC turning, fabrication and welding services from our facility in Amory, Mississippi. We also provide support for manufacturers with CNC programming, tooling and fixture design, solid modeling and drafting, and manufacturing process improvements.

CNC Milling, Fixture Builds, Die Repair

From prototyping to full production runs, Jaco Machine delivers on your most challenging projects. We have the lasted CAD/CAM software, and our dedicated engineering and CNC machine shop team is committed to manufacturing your milled components in the most efficient, precise, and cost-effective manner possible.

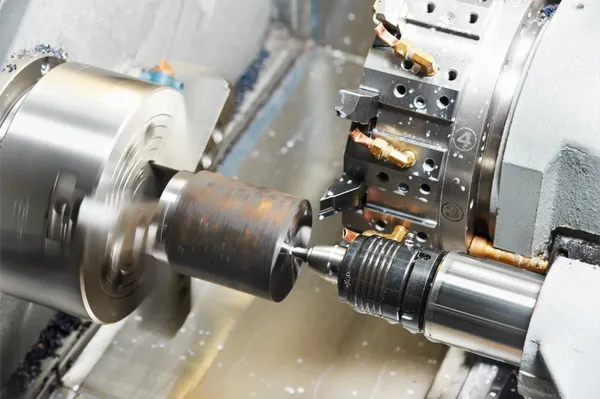

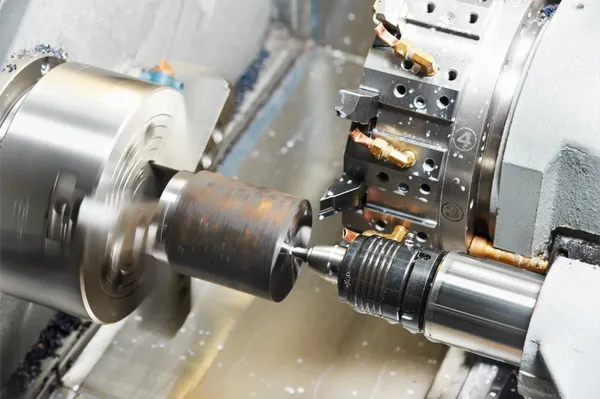

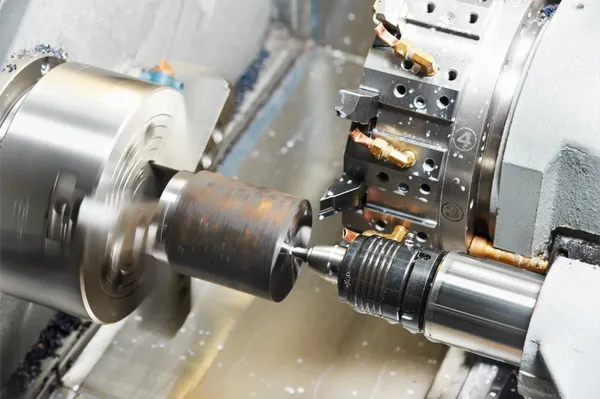

CNC Turning

The Jaco Machine team has extensive experience working with exotic alloys and tight tolerances. We have the CNC turning expertise for all your complex machined component needs and able to support prototype and production needs.

Welding and Fabrication

Jaco Machine can support any weld repair or custom fabrication jobs. We also have the capability to design and fabricate your most complex and challenging projects with innovative and cost-effective solutions.

CNC Milling, Fixture Builds, Die Repair

From prototyping to full production runs, Jaco Machine delivers on your most challenging projects. We have the lasted CAD/CAM software, and our dedicated engineering and CNC machine shop team is committed to manufacturing your milled components in the most efficient, precise, and cost-effective manner possible.

CNC Turning

The Jaco Machine team has extensive experience working with exotic alloys and tight tolerances. We have the CNC turning expertise for all your complex machined component needs and able to support prototype and production needs.

Welding and Fabrication

Jaco Machine can support any weld repair or custom fabrication jobs. We also have the capability to design and fabricate your most complex and challenging projects with innovative and cost-effective solutions.

Jaco Machine’s Aerospace Services

Jaco Machine’s unique experience, equipment, and expertise allow us to provide high level multi-axis milling and turning for the aerospace industry. We also have a strong understanding of GD&T and use proper fixture design to alleviate part stresses.

Jaco Machine’s Expertise in Aerospace

Jaco Machine’s specialty in aerospace machining is branded upon the experience within our organization. We understand the complex datum structures that exist within aerospace design and can design and build fixtures in-house to meet these requirements. Additionally, we are versed and have a strong understanding in the different types of thread and helicoil inserts needed for aluminum Aerospace components as well. We have the multi-axis machinery required to machine your most complicated components.

Jaco Machine’s Aerospace Quality Standard

Jaco Machine has a strong commitment to quality management and is evident through our adherence to ISO9001 and AS9100-based standards. We implement stringent quality control systems and processes, ensuring your components are made with care at every stage of the production cycle.

Jaco Machine: Materials We Use

Jaco Machine is extensive experience working with the following materials:

• Aluminums: 6061, 7075, 7050

• Stainless steel: 303, 304, 316, 317L, 321, 420SS, 416, 440, Inconel, Hastelloy

• Tungsten

• Copper

• Plastics: Delrin, Nylon, PEEK, HDPE, Glass Filled Nylon

CNC Milling, Fixture Builds, Die Repair

From prototyping to full production runs, Jaco Machine delivers on your most challenging projects. We have the lasted CAD/CAM software, and our dedicated engineering and CNC machine shop team is committed to manufacturing your milled components in the most efficient, precise, and cost-effective manner possible.

CNC Turning

The Jaco Machine team has extensive experience working with exotic alloys and tight tolerances. We have the CNC turning expertise for all your complex machined component needs and able to support prototype and production needs.

Welding and Fabrication

Jaco Machine can support any weld repair or custom fabrication jobs. We also have the capability to design and fabricate your most complex and challenging projects with innovative and cost-effective solutions.

The Jaco Machine Advantage

Jaco Machine’s customer service advantage focuses on cost-effective solutions through efficient and streamlined processes designed to increase productivity and reduce total costs for our customers. When you work with us, you can rely on:

- The fastest turnaround times on all quotes and projects

- The highest trained machinists, technicians, and engineers in the industry

- Industry-leading CNC milling, CNC turning, welding, and fabrication

- Manufacturing diversity

- Quick response times for all customer needs

- Able to support a wide range of prototype and fabrication work

- Guaranteed short lead times

- Latest CAD/CAM software

- Conveniently located in Amory, Mississippi near Interstate 22, and the cities of Birmingham, AL and Memphis, TN

- Safe and green business practices designed to support workplace and environmental safety

Jaco's Committed to Excellence

Utilizing our experience and expertise, we strive to exceed the expectations of customers by delivering the highest quality parts and services while providing the best customer service. This is our mission and guarantee!

Jaco Machine’s Partnerships and Past Projects

Jaco Machine has built a strong reputation and proven track record for providing high quality parts and services for some of the industry’s largest companies. These include but are not limited to:

Jaco Machine’s FAQs

Multi-Axis Milling is a manufacturing process, made up of cutting tools moving in four or more directions used to manufacture parts out of metal or other materials by removing excess material with carbide or HSS tools.

CNC milling (Computer Numerical Control Milling) is a machining process which utilizes computerized controls and rotating cutting tools to remove material from the workpiece to produce a specific product or part. The process is suitable for machining materials like metal, plastic, glass, and wood, and producing a variety of custom-designed parts and products.

Production machining involves high-volume manufacture runs of parts, products, and/or components. The process entails removing the excess from a piece of raw material into a desired part or shape. Then, repeating the process to produce large quantities. CNC machining is often used for production machining in which tools like mills, grinders, and lathes are controlled by computers.

Custom fabrication is a process producing everything from steel girders for building and bridges, to the metal parts necessary for aerospace assembly, custom fabricator designs, cuts, and formed metal parts for use in a variety of industries.

Welding is the process of joining two pieces of material together with similar melting points and composites using fusion.

Fabrication is the process of creating a metal product, from layout and design to formation and finishing. A custom fabricator designs, cuts, and forms metal parts for use in a variety of industries. Custom fabricators also provide drilling, welding, punching, and shearing.